High quality mechanical products

Our products

CM International has constantly invested in research and development, technology and instrumentation to guarantee high quality standards and state-of-the-art production methods. These key strengths enable CM International to meet and satisfy the growing demands of an ever-changing market in carrying out its activities.

Processes guaranteeing 100% control over the various processing stages and product traceability guarantee efficient quality control of each individual batch.

Speed, punctuality and quality are the foundation on which CM International has built its relations with all company Stakeholders involved in the various production activities. Today CM International is committed to excellence and innovation with turning, milling, drilling and threading operations to meet any quantity requirement, from small series to large industrialised production.

CM International can supply the finished product, complete with heat treatments, surface treatments, assemblies etc., by machining high quality steel (AVP, C45, 39ncd3 and in any case certifiable), aluminium, brass, bronze and plastics in general.

Transmission components and pulleys

CM International manufactures gears and transmission components of various types.

CM International is able to manufacture a broad range of pulleys used in the transmissions of industrial systems, for example: ceramics systems, food and agrifood systems, systems in the wood, plastic and glass processing machinery sector and in industrial automation in general.

The wide range of pulleys on offer include:

- V-belt pulleys (sections A, B and C);

- toothed pulleys in different materials (steel, aluminium and cast iron);

- L.H.T., HTD, AT profiles

- cast iron V-belt pulleys for glazing lines in the ceramic industry;

- Poly V pulleys;

- pulleys to customers’ drawings.

The customised production of pulleys is wide-ranging and can involve the use of various types of construction materials such as steel, aluminium, cast iron, thermoplastic resins, etc. Multiple types of heat and protection treatments, including induction hardening, carbonitriding, galvanising, burnishing, phosphating and powder coating, can be carried out on the product, subject to agreement with the customer.

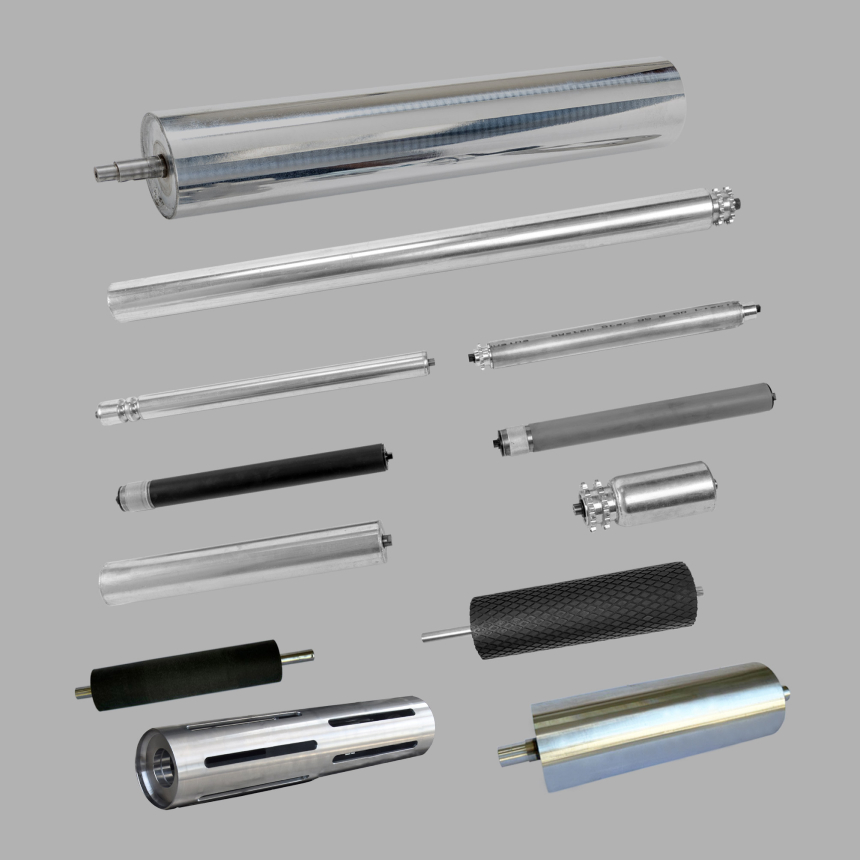

Rollers

CM International produces and manufactures a wide range conveyor belt rollers used in a variety of industrial processes to customer specifications.

Thanks to the experience gained over the decades, CM International has developed and fine-tuned various types of rollers for all types of handing in the ceramic industry.

The surface coating of the proposed rollers can be smooth, grooved or with hot/cold rubberizing in order to meet any conveying requirement. CM International also has a wide range of drive elements: bushings in different materials, crowns, pinions, toothed pulleys for towing suitable for all applications. Designed and manufactured in compliance with the standards, the rollers for roller conveyors must conform to the following requirements:

- compliance with the specifications in the ISO standards;

- use of quality materials and bearings.

Mechanical machining (milling/turning)

With a large and diversified range of machines, CM International can meet its customers’ diverse mechanical machining requirements, thanks to departments in modern workshops equipped with machine tools such as:

- horizontal and vertical machining centres;

- power-operated CNC lathes;

- vertical lathes for large workpieces;

- bar turning lathe;

- sliding headstock machines;

- parallel lathes for small production lots;

- cutting departments;

- slotting and broaching machines for splines and grooves.

The above equipment allows CM International to provide a complete and highly qualified service. The components can also be subjected to heat treatments, grinding, galvanizing, burnishing or EPD before delivery.

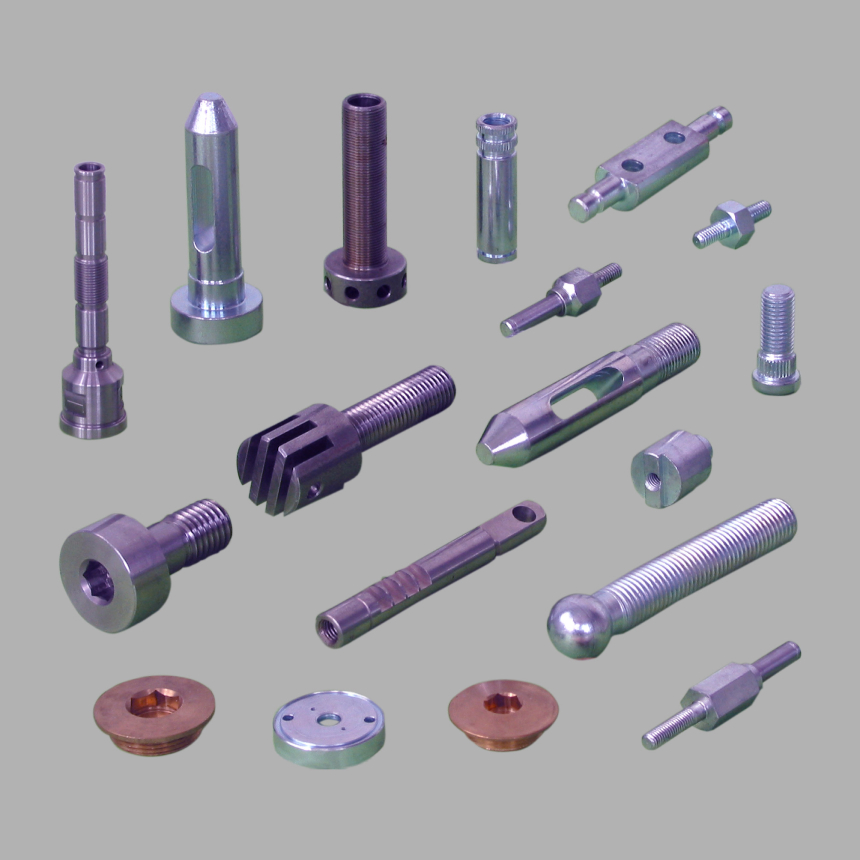

Small parts

For more than 20 years, CM International has been a benchmark in the production of small parts, manufactured using only high-quality materials. The products, developed exclusively on the technical drawings provided by our customers, can meet a wide range of requirements in various industrial sectors.

Plastic details

To complete its product range, CM International manufactures customised plastic parts for industry. The special mechanical characteristics of plastics, their insulating properties and little or no tendency to chemical reactions with other substances allow for various applications, particularly in the following industries: food and agrifood, biomedical, chemical-pharmaceutical, wrapping and packaging, agricultural machinery, construction, automotive and furniture.

In order to meet the needs of its customers, subject to prior agreement, CM International can make prototypes of the parts to be produced before starting the entire machining cycle, and can also carry out feasibility assessments based on the technical drawing.